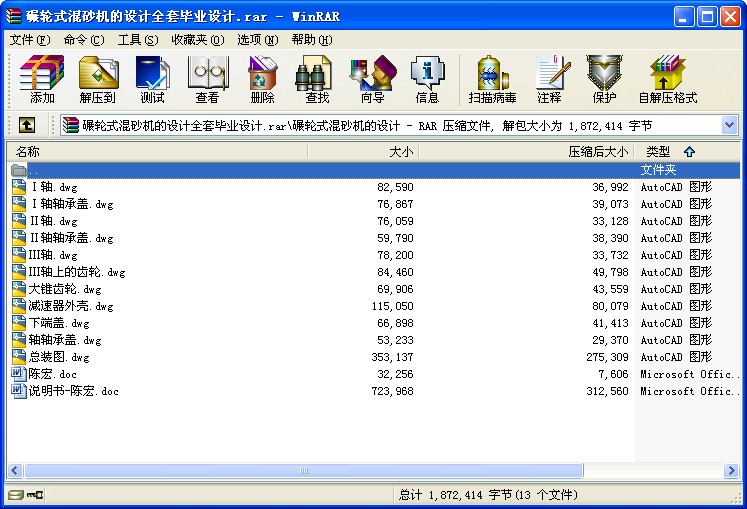

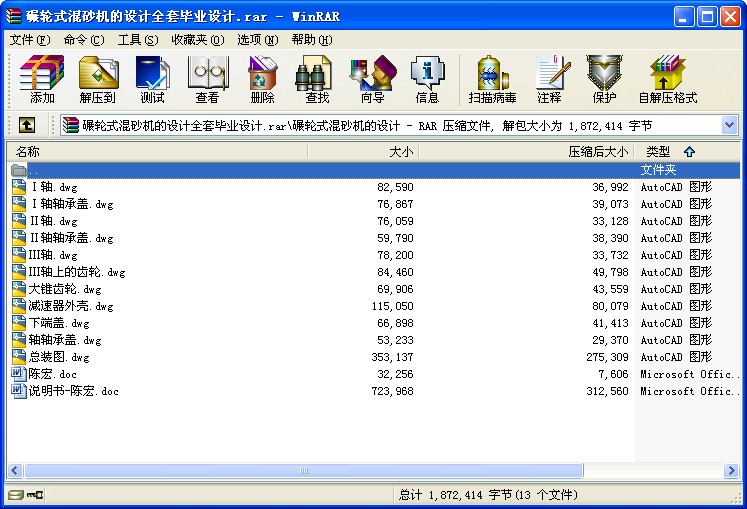

碾輪式混砂機(jī)的設(shè)計(jì)全套畢業(yè)設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 碾輪式混砂機(jī)的設(shè)計(jì)全套畢業(yè)設(shè)計(jì)

摘 要

我這次畢業(yè)設(shè)計(jì)的課題來源于大豐市春城鑄造機(jī)械廠。設(shè)計(jì)主要包括混砂機(jī)的傳動(dòng)部分,齒輪傳動(dòng)的設(shè)計(jì),軸的設(shè)計(jì)與校核,混砂機(jī)總體結(jié)構(gòu)的設(shè)計(jì)分析與計(jì)算。其中S114型碾輪式混砂機(jī)減速機(jī)采用圓錐+二級(jí)漸開線圓柱齒輪軟齒面減速方式,不僅滿足了混砂機(jī)傳動(dòng)裝置傳動(dòng)比大和承載能力高的要求,而且使減速機(jī)具有結(jié)構(gòu)簡單,成本低,易于制造,安裝、調(diào)整要求低,運(yùn)行維護(hù)方便,可靠性更強(qiáng)等特點(diǎn)。在混砂機(jī)設(shè)計(jì)中,還采取了以下措施,以保證其技術(shù)先進(jìn)性和經(jīng)濟(jì)合理性:(1)采用矮刮板,加強(qiáng)對(duì)型砂的混合攪拌作用,并降低其功率消耗;(2)加大卸砂門面積,縮短卸砂時(shí)間;(3)采用輝綠巖鑄石做底盤護(hù)板,增加其使用壽命,減少刮板磨損,改堆焊WC(碳化鎢)為直接焊接硬質(zhì)合金刀片,針對(duì)強(qiáng)度不足,在刮板反面焊上加強(qiáng)筋以增加其強(qiáng)度,經(jīng)改進(jìn)后,一副刮板可正常使用1年左右,刮砂干凈,結(jié)砂很少,負(fù)荷波動(dòng)小。因此,設(shè)計(jì)具有較好的應(yīng)用前景和實(shí)用價(jià)值。

關(guān)鍵詞:輾輪式混砂機(jī);傳動(dòng)裝置;密封;潤滑;減速機(jī)

Abstract

The subject stems from the machine-casting factory of Chuncheng of Dafeng City. The design mainly includes the drive system of the sand mixer, the gear, the design and check of the axle, the analyzing and calculation of the general fitting. The S114 type sand-mixture machine uses a 2-stage spiral gear box which not only satisfies to machine transmission and the requirement of bearing capacity, but also makes deceleration facility simple, economical, contributes to manufacture, makes requirement of installation and adjustment low, and makes reliability strong. In the machine design, the following measures have been adopted in order to guarantee technology advancement and economy reliability. Welded WC (tungsten carbide) is adopted instead of direct welding blade of hard alloy According to strength. The scraper reverse sides of welds are enforced in order to increase its strength. After improvement, a pair of scraper may be used for one year in common. It is clean to scrape sand, with few knot sand and little load fluctuation. So, the design will have better prospect of application and practical value.

Keywords: wheel rolling type sand mixer;transmission;sealing device;lubrication;Gearbox

目 錄

第一章 緒論 1

第二章 傳動(dòng)方案的論證 3

2.1輾輪式混砂機(jī)主要結(jié)構(gòu)及工作原理 3

2.2 方案一、帶傳動(dòng) 4

2.2.1 帶傳動(dòng)的主要優(yōu)點(diǎn) 4

2.2.2 帶傳動(dòng)的缺點(diǎn) 4

2.3 方案二、齒輪傳動(dòng) 5

2.3.1 齒輪傳動(dòng)的主要優(yōu)點(diǎn) 5

2.3.2 齒輪傳動(dòng)的主要缺點(diǎn) 5

2.4 方案三、蝸桿傳動(dòng) 6

2.4.1 蝸桿傳動(dòng)的主要優(yōu)點(diǎn) 6

2.4.2 蝸桿傳動(dòng)主要缺點(diǎn) 6

第三章 機(jī)械傳動(dòng)裝置的總體設(shè)計(jì) 7

3.1 傳動(dòng)裝置的運(yùn)動(dòng)簡圖 7

3.2 傳動(dòng)裝置總傳動(dòng)比 7

3.3 分配各級(jí)傳動(dòng)比 8

3.4 計(jì)算傳動(dòng)裝置的運(yùn)動(dòng)參數(shù)和動(dòng)力參數(shù) 8

3.4.1 各軸轉(zhuǎn)數(shù) 8

3.4.2 各軸功率 8

3.4.3 各軸轉(zhuǎn)矩 8

3.5 將運(yùn)動(dòng)和動(dòng)力參數(shù)計(jì)算結(jié)果進(jìn)行整理并列于下表 9

第四章 機(jī)械傳動(dòng)件的設(shè)計(jì) 10

4.1 錐齒輪設(shè)計(jì)及計(jì)算項(xiàng)目 10

4.1.1 按接觸疲勞強(qiáng)度設(shè)計(jì)計(jì)算 10

4.1.2 有關(guān)參數(shù)修正 11

4.1.3 彎曲疲勞強(qiáng)度校核計(jì)算 11

4.2 高速級(jí)直齒圓柱齒輪的設(shè)計(jì) 14

4.2.1 選擇齒輪材料 14

4.2.2 按齒面接觸疲勞強(qiáng)度計(jì)算 15

4.2.3 校核齒根彎曲疲勞強(qiáng)度 16

4.3 低速級(jí)斜齒圓柱齒輪的設(shè)計(jì) 18

4.3.1 齒輪材料的選擇 18

4.3.2 確定公式中個(gè)參數(shù)值 18

4.3.3 設(shè)計(jì)計(jì)算 19

4.3.4 校核齒面接觸疲勞強(qiáng)度 20

4.3.5 校核計(jì)算 20

4.3.6 計(jì)算齒輪傳動(dòng)幾何尺寸 21

4.3.7 齒輪結(jié)構(gòu)設(shè)計(jì)及繪制齒輪零件圖 21

第五章 結(jié)論 23

參考資料 24

...

看不清楚,換一個(gè)

看不清楚,換一個(gè)

熱門關(guān)鍵詞:

熱門關(guān)鍵詞:

豫公網(wǎng)安備 41072402000322號(hào)

豫公網(wǎng)安備 41072402000322號(hào)