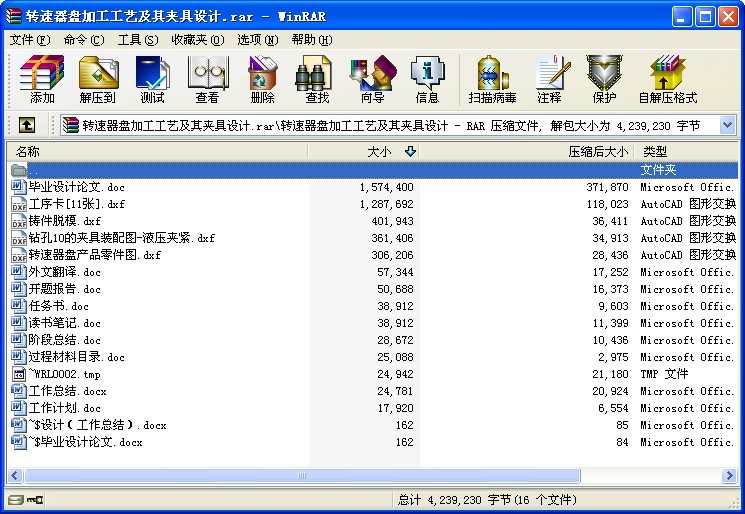

轉(zhuǎn)速器盤加工工藝及其夾具設(shè)計(jì)

- 文件介紹:

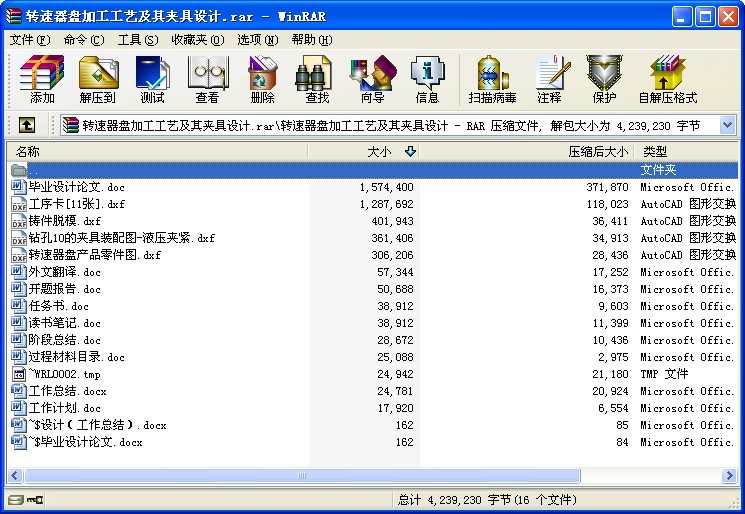

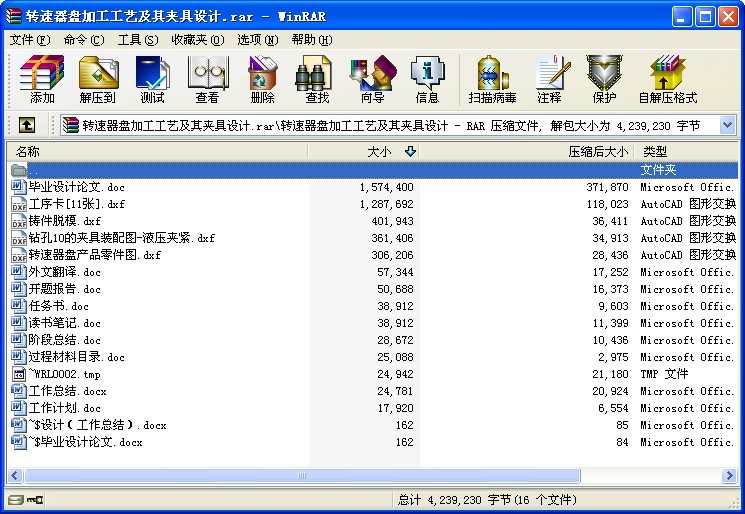

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 轉(zhuǎn)速器盤加工工藝及其夾具設(shè)計(jì)

摘 要

機(jī)械生產(chǎn)是研究產(chǎn)品設(shè)計(jì)、生產(chǎn)、加工制造、銷售使用、維修服務(wù)和回收再生的整個(gè)過程的工程學(xué)科。現(xiàn)代機(jī)械生產(chǎn)技術(shù)越來越發(fā)達(dá),但在新型的生產(chǎn)動(dòng)力普遍使用之前,原有的成熟生產(chǎn)條件依然被使用,在機(jī)械生產(chǎn)過程中發(fā)揮著重要的作用。

2105柴油機(jī)是機(jī)械生產(chǎn)中廣泛應(yīng)用的生產(chǎn)設(shè)備,轉(zhuǎn)速器盤做為其中連接手動(dòng)裝置和油門,實(shí)現(xiàn)無級變速的重要零件,是不可替代的部件。對其進(jìn)行分析計(jì)算,并根據(jù)結(jié)果選用相應(yīng)的加工機(jī)床,設(shè)計(jì)相應(yīng)的夾具,是本次畢業(yè)設(shè)計(jì)的主要內(nèi)容。

設(shè)計(jì)從轉(zhuǎn)速器盤的整體分析開始,經(jīng)過毛壞選料、工藝分析、確定加工規(guī)程,再逐一對要加工的表面進(jìn)行詳細(xì)的計(jì)算,并查找工具書籍進(jìn)行機(jī)床刀具等的選用。最后選取零件上的Φ10mm的孔進(jìn)行了加工夾具的設(shè)計(jì)。

關(guān)鍵詞:機(jī)械傳動(dòng) 轉(zhuǎn)速器盤 夾具設(shè)計(jì)

The Plate Processing Technology and Its Speed Fixture Design

Student: BIN Shang-wen Teacher: DAI xuan-jun

Abstract: Mechanical production is the study of product design, production, manufacture, sale, repair and regeneration of the whole process of engineering disciplines will be added. Modern machinery manufacturing technology more and more developed, but in power prior to the large-scale use of new production, original mature production conditions are still being used, in machinery production plays an important role in the process. 2105 mechanical equipment used in the production of diesel engines, speed disk for which connection manual installation and the gas, important part to realize continuously variable, is irreplaceable part. Analysis and calculation of its, and selected according to the results of the processing machine tools, design the appropriate fixture, is the main content of this graduation. Designed starting from the overall analysis of the speed, after bad materials, process analysis, determine the processing rules and detailed calculations of the surface to be processed one by one, and find the tools selection of books, such as machine tools. Φ10mm on the last selected part design of fixture for hole machining.

Key words: mechanical transmission tachometer disk fixture design

目次

摘 要 I

ABSTRACT: II

1 引言 1

1.1 課題目的和意義 1

1.2 設(shè)計(jì)主要內(nèi)容 1

2 零件分析 2

2.1 零件用途 2

2.2 零件加工工藝分析 2

2.3 加工零件技術(shù)關(guān)鍵問題 3

3 鑄造工藝方案設(shè)計(jì) 4

3.1 毛坯用料及成形方法 4

3.2 鑄造工藝方案的確定 4

3.2.1分型面的選擇 4

3.2.2澆注位置的選擇 4

3.3 鑄造工藝參數(shù) 4

3.3.1加工余量 4

3.3.2拔模斜度 5

3.3.3 收縮率 5

3.3.4不鑄孔 5

3.3.5鑄造圓角的確定 5

3.4型芯設(shè)計(jì) 5

4 機(jī)械加工工藝規(guī)程設(shè)計(jì) 7

4.1 基面的選擇 7

4.1.1粗基準(zhǔn)的選擇 7

4.1.2精基準(zhǔn)的選擇 7

4.2 表面加工方案 8

4.3制訂機(jī)械加工工藝路線 9

4.4 確定機(jī)械加工余量及工序尺寸 9

4.5 確定切削用量 12

4.5.1 工序:粗、精銑后平面 12

4.5.2 工序:粗銑兩個(gè)Φ18 mm的圓柱前端面 14

4.5.3 工序:粗、精銑Φ25mm的圓柱上端面 15

4.5.4 工序:鉆削、鉸削加工兩個(gè)Φ9mm的孔 18

4.5.5 工序:鉆削、鉸削加工Φ10 mm的孔并锪倒角0.5×45° 19

4.5.6 工序:粗、精銑120°圓弧端面 21

5 夾具設(shè)計(jì) 26

5.1 工件分析 26

5.1.1工件的加工工藝分析 26

5.1.2確定夾具的結(jié)構(gòu)方案 26

5.2 繪制夾具總體圖 32

結(jié) 論 33

致 謝 34

參考文獻(xiàn) 35 ...

熱門關(guān)鍵詞:

熱門關(guān)鍵詞:

豫公網(wǎng)安備 41072402000322號

豫公網(wǎng)安備 41072402000322號